Empowering the Dominican Republic’s Fight Against CO2 Emissions with AMECO’s Innovative Scraping Solutions

High performance & reliability when handling bagasse

Customer’s Problem

Reducing CO2 emissions is a pressing concern for many, especially for the Dominican Republic, which faces frequent hurricanes and volatile energy markets. For the country, it is crucial to act as a leader in reducing its carbon footprint while becoming more energy-independent to accelerate the transition toward alternative energy sources.

San Pedro Bioenergy (SPBE), a regional leader in cogeneration technology, aims to convert organic waste from sugar cane, or bagasse, into renewable energy through anaerobic digestion. They also aim to simultaneously generate electrical and thermal energy using a 30MW turbine and a high-efficiency boiler.

However, SPBE faced a significant challenge: drastically reducing carbon dioxide emissions by producing enough power for the CAEI Sugar Factory, the national grid, and a large industrial company while ensuring an aggressive production schedule of 335 days, with only 30 days allotted for maintenance.

The AMECO Solution

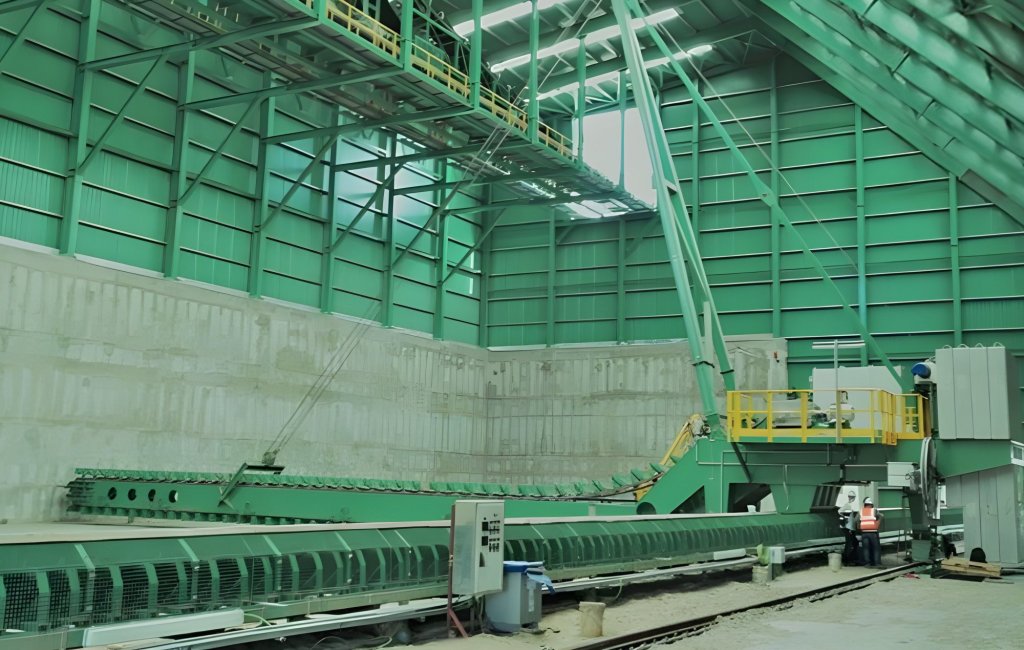

To address San Pedro Bioenergy’s challenges, AMECO provided a state-of-the-art side scraper reclaimer, a key part of their renowned line of bulk-handling equipment. Our machine was specifically chosen for its exceptional ability to manage sticky and cohesive materials like bagasse, which can be particularly challenging to handle due to its tendency to clump and adhere to equipment surfaces. It also benefits from standard AMECO high reliability.

Here’s how AMECO’s side scraper reclaimer delivered unmatched benefits:

- Superior Material Handling Capabilities:

The side scraper reclaimer is engineered to ensure continuous and efficient reclaiming of bagasse, even when it’s wet or has high moisture content. Unlike other OEMs reclaimers that may struggle with clogging or inconsistent material flow, AMECO’s machine has a specially designed scraping mechanism that prevents material buildup, ensuring smooth and uninterrupted operation.

- Enhanced Efficiency in Sticky Conditions:

Bagasse, being fibrous and sticky, can be particularly problematic in bulk-handling processes. AMECO’s side scraper is designed with fit-for-purpose high-torque motors and adjustable scraper blades that maintain consistent pressure against the pile. This feature effectively dislodges sticky material and prevents it from adhering to the machine. This feature is crucial in maintaining high throughput and avoiding costly downtime due to material blockages.

- Custom Guiding System for Reduced Wear and Tear:

AMECO integrated a custom guiding system into the reclaimer, specifically tailored to handle bagasse’s abrasiveness and adhesive nature. This system minimizes the friction and stress on the scraper chains, significantly reducing maintenance requirements and prolonging the equipment’s lifespan. This innovation lowers operational costs and ensures that the machine remains reliable over long production cycles.

AMECO Side Scraper operating at San Pedro Bio Energy

- 99.9%+ Uptime:

The machine’s robust design and ability to handle challenging materials like bagasse contribute to its exceptional uptime, a critical factor for SPBE’s aggressive production schedule. AMECO’s side scraper’s high reliability means that SPBE can maintain near-continuous operation, minimizing the risk of unscheduled downtime and ensuring that energy production targets are consistently met.

- Low Total Cost of Ownership:

Beyond the initial investment, AMECO’s side scraper reclaimer offers long-term cost benefits. Its efficiency in handling complex materials, combined with the reduced need for maintenance and repairs, translates into a lower total cost of ownership. This is particularly important for SPBE, where operational efficiency directly impacts profitability and sustainability goals.

This value proposition is built upon AMECO’s rich set of real-life operational data.

Key Achievements

- 90,000 tonnes of CO2 emissions offset per year that is 10,127,152 gallons of fuel not emitted

- 50% reduction in scheduled maintenance downtime

Póngase en contacto con nosotros y le atenderemos en sus necesidades en cuanto a equipos para manejo de materiales a granel

ContáctenosIndustry

- Power Generation

Material

- Biomass

Capacity (Ton per Hour)

- 1-350

Solution

- Scraping

- - Reclaiming

Storage Configuration

- Indoor

- - Longitudinal

Service

- Supervision & Commissioning

Product

Product type

Side Scraper

Loading rate

70 t/hour

Volume handled

50'000 m3

Boom length

23 meters

Weight

89 tons