How Circular Stockyards Handle High Capacity with Limited Space

Limited storage space for inventory can be a huge issue in any business. Simply because the amount of space you have available to you is limited, does not mean that you cannot run your company and expertly handle those important bulk materials effectively. Circular stockyards are able to handle a high capacity of materials within even the most limited spaces, which is why you may want to look into purchasing one of our systems.

Why do you need stockyards?

Stockyards are an invaluable part of the materials handling process. They can be used as materials buffers, and as a reserve or blended storage for materials that are incoming and outgoing. However, their main functions, at least in our estimation, are to organize and blend materials, while also safeguarding your operation. The highest quality stockyards, like those available at AMECO Group, will deliver the storage you need, while maintaining the highest level of service. And if you choose circular stockyards, they will do this even in the most limited of spaces, when compared to stockyards that are set in a longitudinal configuration.

Why choose circular stockyards?

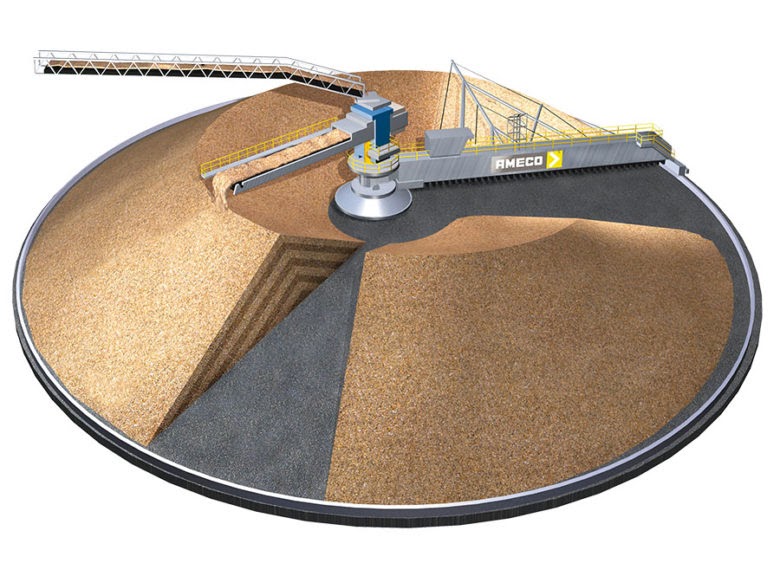

High-capacity circular stockyards are the ideal solution if you have a limited amount of space available to you, but you need a high level of reclaiming capacity. Circular stockyards, by their very nature, take up far less space than other systems as they are stacked in a circular fashion, rather than laid out in a linear configuration. Despite that, they are still able to handle significant quantities of bulk materials including coal, woodchip and paper. If you choose an AMECO circular stockyard, you will also benefit from our homogenization process, which will improve the quality of your output and the performance of your plant by reducing your material’s random variability.

How circular stockyards handle high capacity with limited space

In order to highlight just how high capacity circular stockyards are able to handle high capacity with limited space, it would be a good idea to discuss some of the most popular circular stockyards we offer here and how they work, which should illustrate the benefits of the equipment more concisely.

1. Circular Storage Systems

Our Circular Storage System is fitted with a luffing and slewing scraper arm and a luffing stacker boom. Both of which are supported by a central column, which is a great way to save space when it is at a premium. Both functions are controlled by that one central column, as is the stockyard’s incoming feeding conveyor. This particular stockyard is most commonly used in the power, pulp, and paper industries precisely because it is able to optimize the amount of storage available.

Circular stockyards, like this one, make it easy to preserve significant amounts of bulk material whether indoors or outdoors. If you have a circular stacker reclaimer system, you will be able to use it to handle significant amounts of woodchip, coal, and pulp, which can be left outdoors for prolonged periods of time.

The average length of a circular storage system’s boom is 55 meters, which means you can comfortably store 150,000 m3 of material in bulk. So, although you may have a limited amount of space, you can really do a lot with it.

2. The Circular Homogenizing Stacker Reclaimer System

This system is manufactured in a single ring-piled configuration, which means it can be used to very efficiently stack bulk material. It features a circular stacker on the central column, which means it can be rotated, and a lifting motion utilized. Even in small spaces. Its height is limited to only that above the zenith of the pile in order to minimize the amount of dust and emissions that are made when in use.

The Circular Homogenizing Stacker Reclaimer System also features a reclaimer bridge, which circles around the central column and enables the reclamation of materials (like limestone and wood chips) to take place from the pile’s face via a harrow, directly to the bridge reclaimer. Sweeping motions homogenize the bulk material as it travels, allowing it to effortlessly slip onto the pile base where it can be reclaimed via the reclaiming arm to the output conveyor. You may not think that this can be achieved in a relatively limited space, but its unique design and innovation make it a reality.

3. Circular Portal Scrapers

AMECO’s circular portal scraper is a slewing portal reclaimer that consists of a circular rail on one side and a central supporting column on the other. It was created primarily for use in indoor set-ups where the reclaim conveyor belt is located underground. Thanks to the equipment’s ability to shift its articulation between the primary and secondary reclaiming arms, it is ideal for working with and in high capacity situations, and in spaces that have a limited amount of height.

These kinds of equipment are typically used for bulk coal, fertilizers, and sulfur. AMECO uses a reclaim conveyor that’s situated underneath the central column by way of a chute, to really maximize its impact in smaller spaces. If you’re wondering how the reclaiming arm is supported, it’s held up by a portal reclaimer that’s fixed to the central column with a slewing ring and no gear. This means its length can be limited to approximately 65 meters, again making it perfect for smaller buildings. If you do need more storage than it can offer, a product retaining wall can even be erected on the outskirts to boost capacity.

Investing in Circular Stockyards

As we have hopefully illustrated, it really is possible to handle high capacity bulk material loads in a limited amount of space, and high capacity circular stockyards are the way you can most effectively do this.

If you want to find out more about the use of circular stockyards in your industry, how they work, or which solution would best suit your business, why not get in touch with our dedicated and knowledgeable team here at AMECO? With almost 90 years in the business and some of the best engineers in the industry, you can trust us to deliver the best solutions for you and your business, no matter what they may be. So, what are you waiting for? Get in touch with us and transform your business today. Interested in the quality services offered at AMECO? Check out our brochure to learn more.