Circular Stockyards for Bulk Material Handling

To create wood storage AMECO’s Circular Stockyard System offer the perfect solution when space is limited, and high reclaiming capacities are required.

The most economical automated storage facility using a Stacker Reclaimer System in outdoor applications.

AMECO’s Circular Stockyard solutions are used for large quantities of pulp or woodchips in Paper Mills, but can also be used for other Outdoor Bulk Materials such as coal.

AMECO also offers homogenization where the chemical component of the raw material varies. This process is important to optimize plant performance and control product quality. It is used to reduce the random variability of raw materials by implementing stockpile management techniques.

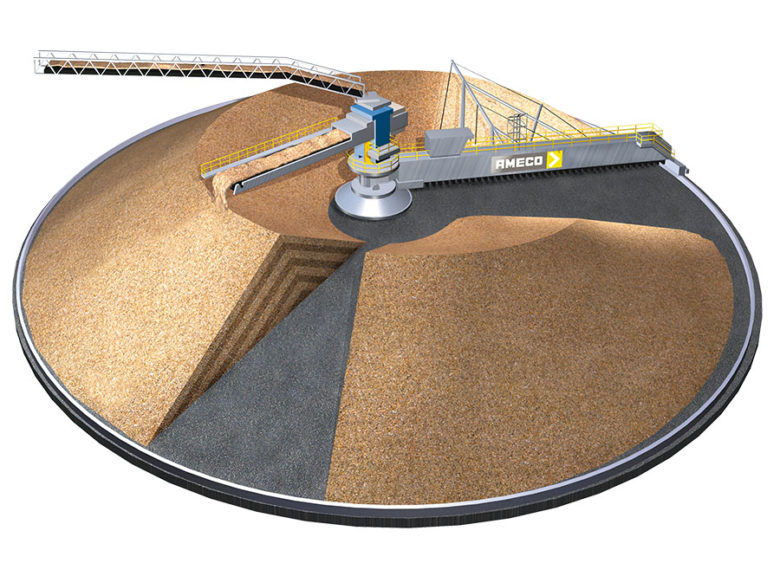

Circular Storage Systems

The Circular Storage System (CSS) is equipped with a slewing and luffing Scraper arm as well as a slewing and luffing stacker boom. The Stacker and the Reclaimer are supported by one central column which also supports the incoming Feeding Conveyor. This Circular Stockyard is used mostly in the Pulp and Paper Industry or in the Power Generation Industry since it optimizes the storage volume on a low surface Stockyard.

Circular Stockyards allow the preservation of large quantities of Bulk Material in both outdoor and covered storages. Circular Stacker Reclaimer Systems are mostly used for large quantities of pulp or woodchips, but they can also be used for coal or any other Bulk Materials that can be left outdoors.

The boom length for a Circular Storage System goes up to fifty-five metres, allowing thus a storage of 150,000 m3 of Bulk Material.

Circular Portal and Semi Portal Stacker Reclaimers

The Circular Portal Scraper (CPS) is a Slewing Portal Reclaimer supported by a central column on one side and by a circular rail on the pile’s outskirts. It has been designed for indoor applications where the Reclaim Conveyor is underground.

Due to the arm articulation between the primary and secondary reclaiming arm, this design suits high capacity needs and low building heights. Circular Portal Scrapers are used for handling many types of Bulk Material such as fertilizers, coal, sulphur.

AMECO’s Circular Portal Scraper loads a Reclaim Conveyor located below the central column via a centrally located chute. The reclaiming arm is supported by a Portal Reclaimer where the primary side is attached to a central column using a slewing ring without a gear. The circular slewing movement is arranged using the secondary side travelling carriage of the Portal Reclaimer.

A normal length for a Portal Reclaimer arm is usually around 65 metres. For larger storage capacities, AMECO can install a product retaining wall at the outskirts of the pile.

Circular Homogenizing Stacker Reclaimer System

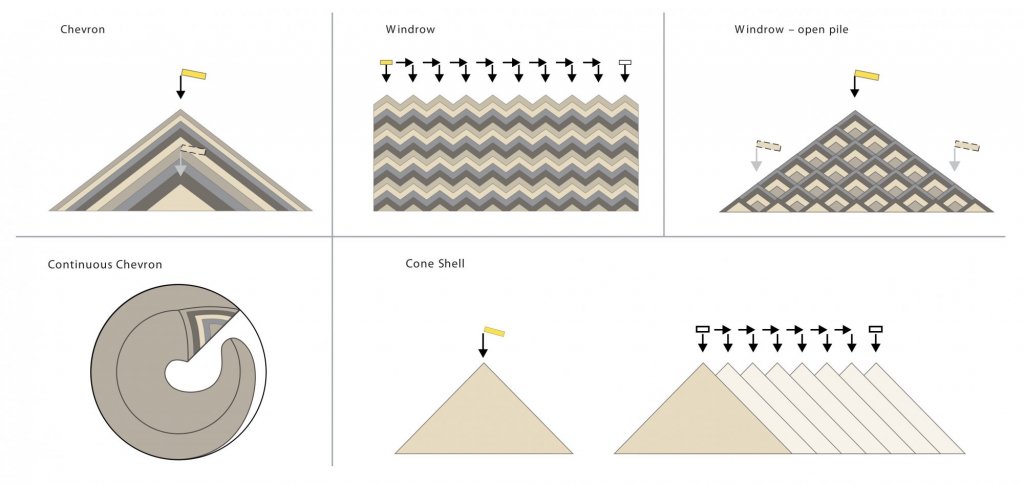

The Circular Homogenizing Stacker Reclaimer System (CHO) stacks Bulk Material in one ring-shaped pile. The Circular Stacker is located on the centre column, allowing rotation and luffing motion, hence building the material in a chevron or cone shaped shell. Its height above the top of the pile is kept at a minimum distance to reduce dust emission.

The Reclaimer Bridge rotates around the central column. Reclaiming Bulk Material such as woodchips, limestone, or coal, takes place from the face of the pile by a harrow travelling on the Bridge Reclaimer. The sweeping movements of the harrow homogenizes the Bulk Material as well as allows the Bulk Material to slide on the pile base. It is then reclaimed to an Output Conveyor via the reclaiming arm located below the bridge structure.

All major stacking methods supported – chevron, windrow, axial, conal (CSS only) — can be selected by the operator using the terminal