Optimizing Woodchip Storage: AMECO’s Space-Saving Solution for SCG Thailand

High Performance & Robustness in a Compact Space

Customer’s Problem

SCG faced a daunting challenge: managing an enormous 150,000 m³ pile of woodchips within a mere 200 square meters, surrounded by existing businesses and residential areas. This limited space demanded an innovative solution that could maximize storage efficiency while minimizing disruption to the surrounding environment.

The AMECO Solution

AMECO Group’s Circular Stockyard System (CSS) was the perfect answer to SCG’s problem. Unlike traditional linear storage systems, the CSS is designed to stack materials circularly, allowing for maximum utilization of the available space. In SCG’s case, this meant fitting a large volume of woodchips into a footprint that other solutions could not accommodate.

AMECO’s solution stood out against the competition, which either lacked the necessary expertise or offered solutions that were not adaptable to SCG’s specific needs. Our machine integrated seamlessly into SCG’s workflow, avoiding the need for disruptive changes to their existing operations by delivering the following value proposition:

- Optimized Space Utilization: The CSS design enabled SCG to store 150,000 m³ of woodchips within just 200 square meters, avoiding the need for extensive civil engineering modifications.

- High-Quality Construction: Made from premium-grade steel, the system ensures durability and robustness, critical for the continuous operation required by SCG.

- Operational Efficiency: The system not only fulfilled SCG’s stringent space requirements but also enhanced the consistency and quality of the woodchip output by significantly reducing variability, thanks to AMECO’s advanced homogenization process. Additionally, our intuitive machine controls were designed to be user-friendly for operators new to this type of equipment, while offering the durability and functionality expected by experienced teams. This ensured that the system was immediately operational, minimizing downtime and maximizing productivity from day one

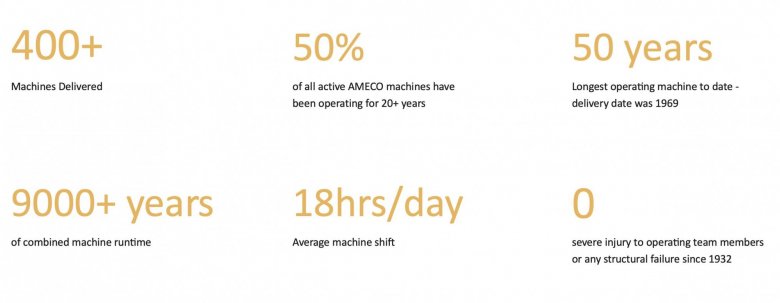

This value proposition is built upon AMECO’s rich set of real-life operational data

Key Metrics

The installation delivered impressive results:

- Storage Capacity: The woodchip stockpile reached a capacity of 150,000 m³, with a pile diameter of 120 meters (393 feet).

- Stacking and Recovery Rates: The system efficiently stacked woodchips at a rate of 300 TPH and recovered material at 125 TPH.

- Global Impact: At the time of its commissioning, the CSS at SCG was one of the largest over-pile stacker reclaimers in the world in terms of pile capacity.

Beyond the Installation: AMECO After-Sales Support

AMECO’s commitment to SCG didn’t end with the installation. We provided ongoing support, including custom spare parts delivery, regular inspections, and residual lifetime extension (RLA) services.

In June 2022, AMECO experts conducted a comprehensive analysis of SCG’s circular storage system, which has been in continuous operation since its commissioning in 2013.

Particular attention was given to the central slewing ring—a critical component responsible for the rotation of the reclaimer arm. Our team provided SCG with a detailed maintenance roadmap, including 11 solutions aimed at optimizing operational expenditures (OPEX) and extending the machine’s life expectancy.

Get in touch with us for your bulk handling equipment needs

Contact usIndustry

- Pulp & Paper

Material

- Woodchips

Capacity (Ton per Hour)

- 1-350

Solution

- Reclaiming

- - Stacking

- - Stockyard Management

Storage Configuration

- Circular

- - Outdoor

Service

- Inspection

Product

Product type

Circular Storage System (Stacker+ Reclaimer)

Loading rate

2000 t/hour

Volume handled

150'000 m3

Boom length

27.5 meters

Weight

205 tons